LED backlighting

Technical parameters:

| Type ILST-NPV-480W-2021 |

| Previous types ILST-NPV-480W |

| Smart No |

| Battery capacity Ah |

| LED SAMSUNG, CREE, OSRAM |

Product information

- Name of the product: LED backlighting

- Certificate: CE (European Compliance)

- Year of production: 2021

In October 2010, at the request of the Kecskemét NJE Faculty of Horticulture andRural Development, we started research to determine the effects of seedling cultivation with backlighting.

For the parallel series of experiments, we developed a special LED backlight that patterns the light spectrum emitted by the sun in almost the same way.

Our experiments showed that supplemental lighting has a positive effect on plant development, but further experiments did not produce a significant difference between the two types of supplemental lighting.

We can prove beyond reasonable doubt that LED backlighting can replace conventionally used mercury based halogen lamps.

Benefits of LED backlighting

In our experiment, we found that there is no significant difference in results between the two types of lighting, but it has significant advantages in other aspects. By using LED lighting, power consumption can be reduced by up to 40% for the same results.

Because commonly used halogen lamps generate irrationally large amounts of heat during operation (which the plant does not need), it becomes necessary to provide a cooling solution in the greenhouse, which results in additional costs. This is not necessary for lighting that uses LED technology, as it does not produce nearly as much heat as a conventional lamp.

It also has a longer lifetime! On average, a LED light source can withstand 30,000 to 50,000 hours of operation.

If we use the backlight for an average of 8 hours a day, it is still able to work for a minimum of 10 years!

The radiation dose of backlighting is one of the most important factors due to plant development, as the radiation dose varies inversely with the square of the distance!

To put it simply, if we use two different light sources with the same radiation factor, but in one case the distance from the plant due to the emitted heat radiation is approx. 3 meters (conventional light sources), on the other hand, the other light source (LED) can be placed at a distance of up to 1- 1.5 meters from the plant, we can count on a 40-50% plant development yield! Its benefits also include a longer service life.

Currently used grow lighting and its properties

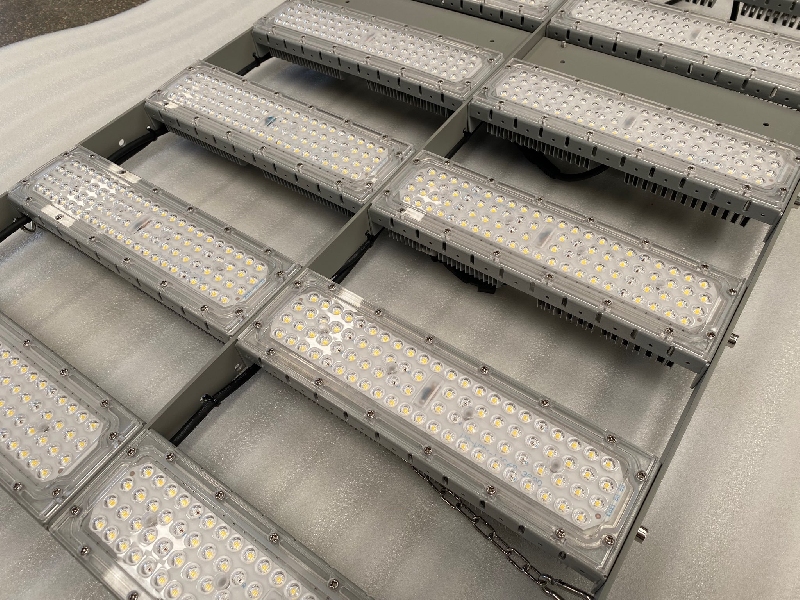

Our company currently uses self-developed Samsung and Osram LED chips.

We use 100% passive cooling for our grow lights. This provides low heat generation and good heat dissipation which is optimal in a greenhouse environment. We use a modular design with an output of 480W, in order to make assembly and repair cost-effective and fast. As a result, if the lamp is damaged, it can be repaired by avoiding a complete replacement or hard-to-do repairs. The lamp elements (due to their modularity) can be adjusted separately to the desired angle, to achieve the optimal lighting level. Adjustment at an angle is important because as the plant develops, not only does its height change, but the foliage also expands horizontally! Our experiments proved the importance of angle adjustment!

We use MeanWell drivers with dimming function that enable the user to adjust brightness according to the plant’s needs (they can be operated one by one, or you can istall a centralized control unit that can dim up to 15 lights at once).

During our designing process, we paid special attention make our product resistant to the high humidity found in greenhouses. The lighting is therefore IP66 protected.

Guarantee

Our company provides a 5-year guarantee for our products!

We undertake the supply of spare parts beyond the guarantee for a minimum of 15 years!

For more information, feel free to contact us: info@ilst.hu